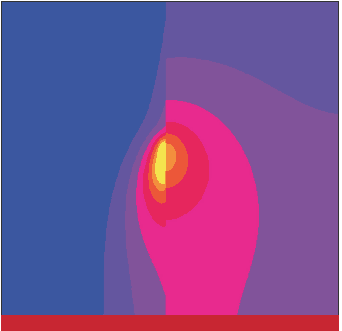

Welding is a common practice in the automotive, aerospace, railways, ship building, and machinery industries. It allows for the joining of components by subjecting them to intense localised heat that melts and coalesces the material in the welded region, forming a permanent joint.

Multiple process parameters influence the effectiveness of the welding, which include energy source, shape and size of the melt zone, heat affected zone, and speed.

Understanding and improving this challenging process through physical iteration can be time consuming and expensive. MSC’s Marc, a nonlinear finite element analysis tool, can provide the required insights needed to solve these parameters in a cost-effective manner.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...