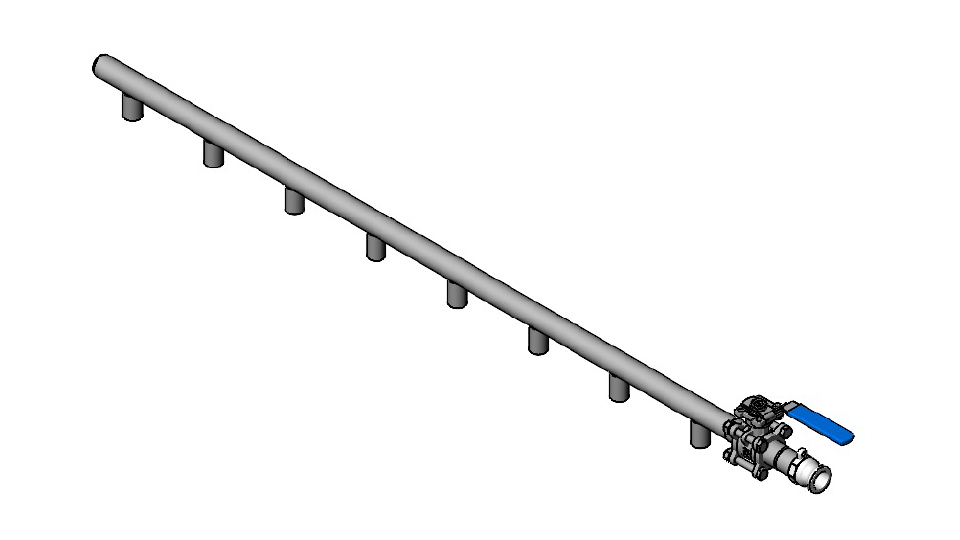

Spray bar applications are common in food manufacturing and many other vital industries, enabling the positioning of nozzles along an axis, increasing the coverage area and precision of a spray.

Currently, process engineers may rely on multiple suppliers to deliver a functional spray bar. This can add significant project risk in the form of delays, spray bar quality issues, increased costs and uncertainty regarding the accuracy and precision of the spray. In addition, process and operational managers are often left to deal with the inefficiency costs post-installation.

The Spray Nozzle People’s (SNP’s) easy-to-configure spray bars mean engineers can focus on other projects through the convenience of dealing with a single supplier who can efficiently design and manufacture a spray header that delivers cost savings not only at the point of sale but also during operation. The spray bars are designed with future maintenance in mind, ensuring downtime and the resulting costs are minimised.

SNP’s spray bars are suitable for spray applications such as coating, cooling and moistening in meat, fruit and vegetable, dairy, pre-prepared food and fish manufacturing and processing operations.

Expert nozzle selection and placement transforms a basic spray bar into a precision solution

Swap-in replacement bars and bars for new processes

SNP designs spray bars for new processes or swap-in replacement bars for existing spraying operations.

Nozzle wear is a key issue over time that impacts production quality and product cost. SNP has designed its swap-in replacement spray bar service to address the challenges and time costs associated with finding replacements for obsolete or worn nozzles that match customers’ existing spray bars. The swap-in replacement spray bar service ensures simple integration, improved spray precision and design features that enable faster future replacements.

For new spray processes, SNP’s service removes the design burden and reduces the number of suppliers required to achieve customers’ spray goals.

From initial enquiry, SNP aims to deliver a complete spray bar solution in 4-5 weeks.

Why use a spray bar?

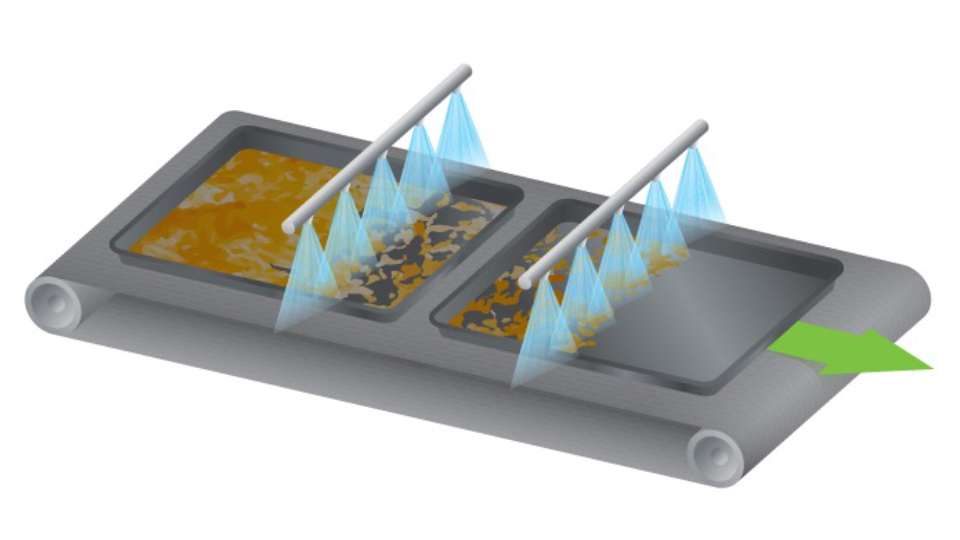

- Consistent spray coverage: A multi-nozzle spray bar ensures even distribution, eliminating the uneven patterns typical of single nozzles.

- Enhanced cleaning power: Spray bars allow for narrow-angle, high-impact nozzles to be placed closer to the target, improving cleaning efficiency compared to a single, wide-angle nozzle (see image).

- Precision in targeting: For conveyors with multiple product lines, spray bars can precisely position nozzles to avoid wasting spray media between product gaps.

An efficient spray bar delivers key benefits to food manufacturers, including:

- Achievement of ingredients tolerances

- Improved product quality

- Reduced water/ingredient consumption

Why buy a spray bar from a nozzle specialist?

Spray bars are quite simple things to make. At the end of the day, they consist of a piece of pipe with a few welded-on threaded holders for the nozzles. So, why buy from a specialist company like SNP?

The construction of the spray bar itself is not difficult. Any competent fabricator can make one. It is the design of the bar and where to position the nozzles correctly and optimally that makes a precision product. This involves an understanding of spray nozzles and sprays in general. SNP uses its expert knowledge of spray nozzles and works backwards. The final layout of the spray bar is fully determined by specialist knowledge of the individual spray patterns that need be generated to deliver optimal spraying.

Says SNP Managing Director, Ivan Zytynski:

“Spray bars are a natural addition to our spray solutions range, building on our expertise in specifying and supplying spray nozzles to industry for the last four decades. We are delighted we can now provide a quick and efficient spray bar specification service in line with our mission to deliver hassle reduction, optimise efficiencies and give our customers peace of mind.”

About SNP

SNP supplies spray nozzle solutions to industries worldwide, underpinned by friendly, knowledgeable, efficient customer service. The SNP range includes tank washing nozzles, IBC cleaning systems, hydraulic nozzles, air atomising nozzles, custom piping assemblies and spray accessories. The company offers in-depth technical and application support, ensuring customers always have the correct spray solution to meet their needs whether they are a large multinational company, a small business or design engineer and whatever the size or stage of their project. SNP is proud to operate with ISO 9001 certification, ensuring its spray bar systems meet the highest standards of quality and reliability.

enquiries@spray-nozzle.co.uk 00 44 (0) 1273 400092 www.spray-nozzle.co.uk

Start a spray nozzle specification here

Learn more about spray bars here

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...