The cleaning of intermediate bulk containers (IBCs) is a common application in many industries. Often, specialist external companies are used to take away and clean IBCs or smaller companies will clean IBCs manually which may be ineffective, particularly for hygienic environments. The new IBC Cleaning Station system from SNP allows for quick, safe and cost effective cleaning of IBCs in house.

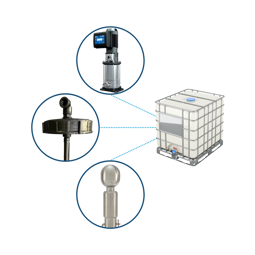

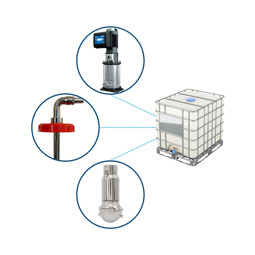

SNP’s plug-and-play system consists of:

The IBC kit is incredibly easy to operate and is an ideal solution for businesses looking to clean up to 50 IBCs a week. It simply needs connecting to a suitablepower source and water supply. The lance with cleaning head is screwed into the IBC though a standard IBC lid and the system is ready to go.

Two models

The system is available with either an Orbitor Eco rotary jet cleaning nozzle – the Advanced Model – or an RSB25 rotary spray head – the Basic Model. The Advanced version is suitable for even heavy or sticky residues and the Basic for light to medium residues. The kits can also be supplied without the pump and control panel.

Advantages

The IBC Cleaning Station provides numerous advantages, including:

Cleaning times & water consumption

The time it takes to clean an IBC depends on the nature of the residue and the type of cleaning head deployed.

Both cleaning heads have a flow rate of 58 litres per minute. However, the OrbitorEco rotary jet fast cycle cleaning head will clean the IBC some 2-3 times faster than the RSB25 spinning head.

It’s important to note that, for very light residues, the RSB25 may be the most water efficient; rotary jet cleaners such as the Orbitor Eco must operate for a certain amount of time to complete a full cleaning cycle. If they run for anything less than 2 minutes, parts of the IBC could be missed because the cleaning jets will not have been brought to bear on each part of the IBC. This means they’re going to use a minimum of 116 l/min (2 minutes at 58 l/min) to clean any given tank. The RSB25 has no such limitations and will give a complete coverage instantly, so if they can clean the IBC in under 2 minutes, and if the residue is light enough for it to do that, then it becomes the most water efficient option.

How much does an IBC Cleaning Station cost? Find out here.

To get answers to commonly asked questions about SNP’s IBC Cleaning Station, please watch the video explainer series here.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...