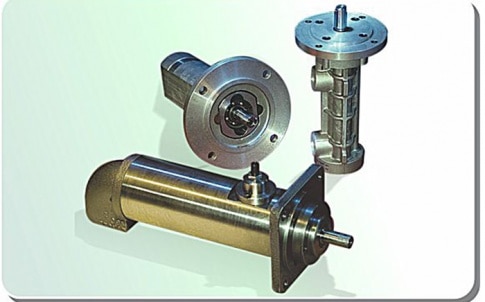

These screw pumps are volumetric self-priming pumps suited to handle oils and liquids with a minimum lubricating quality. The design simplicity makes these screw pumps intrinsically reliable and efficient.

The accurate hydraulic balance and the special profile of the screw thread guarantee a continuous flow with minimum pulsations and turbulance, resulting in extremely low noise levels even at high rotational speed.

The screws epicycloidal profiling is developed through a complex computerised calculation which not only perfectly defines their shape, but also controls the production with continuous monitoring of machinery process, consequently assuring a high degree of repeatable quality.

The high quality level of these screw pumps is guaranteed by a final testing on 100% of the manufactured products.

Characteristics

» Compatible with a wide range of viscosities from 1 to 12,000 cSt and above.

» Efficiently working also at very low temperatures (-20°C).

» High self-priming capacity.

» High rotation rates = minimizing the size and cost of the pump.

» Steady flow rate = maximum efficiency in heat exchange applications.

» Special design for systems with entrained air in the lubricant = minimizing the vibrations and noise caused by air.

» Minimum sensitivity to particle pollution = longest life of the pump and circuit.

» Continuous operating pressures up to 130 bar, peak 200 bar.

» Pulsation-free = maximum efficiency of filtering applications.

» Extremely quiet.

Product Options

Screw pumps: standard according to API 676, for mineral and lubricating oils also fluids with low lubricating properties (water + oil, HFC, LFO, HFO). Flows up to 5,000 litres per minute and pressure up to 130 bar (200 bar peak).

• SAE counterflanges.

• Motor pump sets: close coupled, AC or DC electric motors.

• Pre-assembled systems: with bell-housing and coupling arrangements.

• Skid mounted pumps: with or without motor but suitable for horizontal or vertical mounting.

• High efficiency Air/Oil Heat Exchangers: up to 14,000 kCal/h (16kW).

• Off-line filtration systems (filtration trolley) and complete stand alone systems, also for machine tools).

• Relief valves: Flow rate from 50 to 1,200 litres per minute and pressure up to 40 bar.

• ATEX approval for use in explosive atmospheres: ATEX Zone 0 & 1

For detailed information and technical specification catalogues seewww.jbj.co.uk/screwpumps.html

A helpful guide to pump drives: www.jbj.co.uk/how-to-select-the-right-pump-drive-for-an-application-learning-the-basics.html

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...