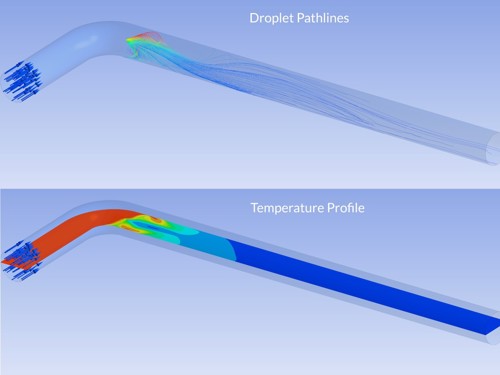

CFD (Computational Fluid Dynamics) is a method for modelling complex fluid flows and can be used to model the movement of sprays in a particular gas flow and to help optimise gas scrubbing applications.

Gas scrubbing systems can be complicated; there are tens or hundreds of millions of individual drops of varying sizes moving around and gas flows are often complex and turbulent.

Very simple spray trajectory plots, which can be obtained from simple software, into simple uniform gas flows at constant speeds are sufficient for the testing of very basic assumptions.

However, they won’t truly model real life events.

For many scrubber designs, these very basic assumptions can be used with the addition of extra liquid to ensure that they’re going to work.

The very worst case assumptions can also be looked at and the scrubber can be designed to cope with these worst cases.

Whilst this worst case approach is widespread and common, it is clear that it will not produce the most optimum of results/scrubber designs.

It is not practical to run real life tests for most scrubbers due to the high costs involved and because of the extremely hot temperature. They are also full of lots of pollutants, so building working models and then conducting a performance test with different spray scenarios is hardly practical.

CFD provides a way of testing the scrubber efficiency without having to build an actual scrubber.

It is halfway house between having a live working model or using basic assumptions and worst case scenario assumptions. By selecting a range of spray nozzle candidates and measuring their important drop sizes in the lab, the scrubber design and optimisation can be improved.

Understanding drop sizes and their impact is extremely important. DV0.9 is used to measure the heavy drops and the DV0.1 is used to measure the fine droplets. The DV32 Sauter mean is a measure of the average drop size or surface area.

All of these can be tested in the lab with different nozzles that are being considered. They can be tested at different pressures to form the raw input data and build up a picture of the sprays from various nozzle scenarios.

The data can then be input into the CFD software along with the gas flow data and the geometry of the scrubbing chamber to start modelling what’s going to happen.

The importance of a proper spray lab

The problem with the modelling of data of this nature is that CFD is not simple. It requires a lot of computing power and the initial lab data is needed to act as an input into the CFD calculations.

A proper spray lab that understands the subtleties of drop size measurement techniques is needed and is an absolute must; if you don't have the good spray lab data going into the initial CFD calculations, the results are going to be poor. Having a proper spray lab that can measure those drop sizes and understands how to do that properly, is absolutely vital input for any CFD calculations.

Once that is all input, it is possible to model what the spray is going to do and start to calculate the absorption rates, mass transfer and heat exchange within the gas. By using different nozzles or feed pressures, several different spray setups can be tested. A picture of what's going to be the optimal scrubber design will start to build up.

Through our core nozzle supplier, BETE Fog Nozzle in the US, our team have access to all the required spray labs and CFD capabilities.

Because BETE is one of the world's leading spray nozzle manufacturers, you can rest assured that those vital inputs into the CFD, (the measuring of the drop sizes, testing of the different sprays), are going to be correct. Therefore, the models that will be produced are going to be useful and reliable.

The cost of CFD has come down considerably in recent years because it is primarily driven by computing power and it takes a lot of this to do CFD. As computing power and costs decrease, so does the cost of CFD. However, it's still not a cheap process.

The initial lab work and empirical testing of different spray setups still need to be conducted, followed by hefty computing with specialist technicians to understand how to use the CFD programmes and how to obtain results.

So, whilst CFD isn't going to be used for every single basic scrubber design, it is coming down in cost and helping optimise and improve scrubber designs. This will start to become the norm and for scrubber design, this is really positive news because if scrubbers can be optimised and made more efficient, pollution will be reduced which helps save the planet.

Here at SNP, CFD is something we're fully capable of deploying in scrubber design – we are qualified to do it and we have the partners in place to conduct the initial lab work and testing.

If you're looking to optimise scrubber designs, we are a good company to approach and discuss how we can deploy CFD technology to optimise your scrubbers.

To discover more about CFD modelling for gas scrubbing, please click here to receive information and advice.

Or contact SNP on:

01273 400092

www.spray-nozzle.co.uk

UK Enters ‘Golden Age of Nuclear’

Apologies if this is a duplicate post - a glitch appears to have removed the first one: > While I welcome the announcement of this project, I note...