There are four basic spray patterns delivered by industrial spray nozzles: full cone, hollow cone, flat fan and solid stream.

Misting, spiral full cone and square spray patterns are all derivatives of these basic four.

In the first of our Nozzle Knowledge Series, we look at the properties of each pattern and its derivatives below.

Prefer to watch a video? Please click here to see our short introduction to spray patterns.

BASIC SPRAY PATTERNS

FULL CONE: A full cone nozzle generates a filled-in circle of spray if you are looking face on at the nozzle. The fluid distribution is even across that circle.

This spray pattern has the lowest impact of all the spray patterns.

You can have a spray angle, which is defined as the angle of that cone, of between 30°-170°.

Drop sizes are typically medium for any given pressure.

HOLLOW CONE: A hollow cone nozzle is defined as giving a circle of spray rather than a filled in circle of spray; all the fluid is pushed towards the edge to form a band of spray.

Again, this is a low impact spray pattern.

It has the smallest droplet size of all four basic spray patterns.

FLAT FAN: A flat fan nozzle produces a line of spray rather than a circle. And because the fluid is being concentrated into a smaller area, this spray pattern offers higher impact.

Similar to cone nozzles, flat fans can have a spray angle between 10° - 145° degrees.

Typically with these types of spray nozzle, the drop size is larger.

SOLID STREAM NOZZLE: Essentially, this is a 0° flat fan nozzle. It has a much higher impact because again, all the fluid is being concentrated into a point.

There isn’t a drop size with this nozzle type. It is not designed to atomise the fluid, but rather to keep it in a coherent laminar flow.

BONUS SPRAY PATTERNS

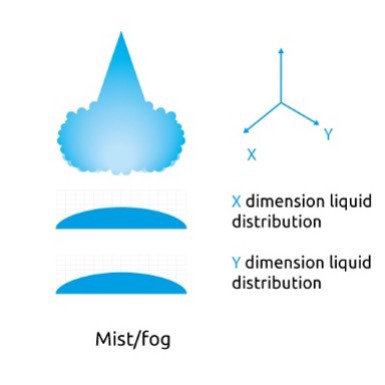

MISTING: This is not a true spray pattern; misting patterns will either be a hollow cone or a full cone nozzle, typically running at higher pressures.

The hollow or full cone pattern is visible near the nozzle orifice but, because of the increased atomisation, it turns into a mist quite close to the nozzle.

The outcome is an amorphous mist which doesn’t have a proper pattern. It is wafted around by the air.

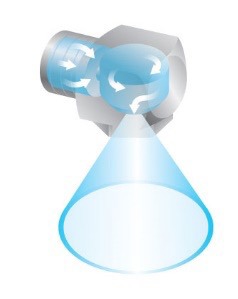

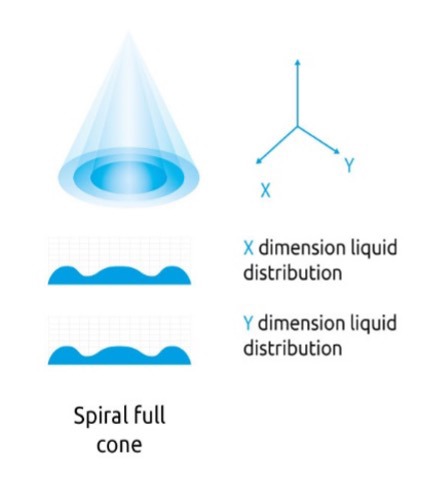

SPIRAL: These can either produce a full cone or a hollow cone, but the pattern is slightly different.

The pattern is derived from concentric hollow cone patterns that are formed by the spiral shape of the nozzle and the nozzle can be designed to have these concentric hollow cone patterns overlapping to form an approximate full cone pattern. But there will be considerable variation at different parts of that full cone.

They can also be designed so that all the hollow cone patterns converge into one big hollow cone pattern. This could have some implications for fluid distribution.

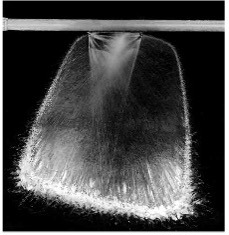

SQUARE: Square pattern nozzles are pairs, and they spray into each other and interact to form a square pattern.

This can be useful when trying to fit the spray into a rectangular or square shape.

If you have any further questions on spray patterns, please get in touch. To learn more, visit www.spray-nozzle.co.uk.

About SNP

SNP supplies spray nozzle solutions to industries worldwide, including the largest engineering, food processing, chemical and petrochemical companies, as well as a vast array of small and medium sized enterprises (SMEs). The company’s product range includes tank washing nozzles, hydraulic nozzles, air atomising nozzles, custom piping assemblies and spray accessories as well as disinfecting and washdown systems.

SNP is as skilled in advising design engineers at the beginning of projects as it is recommending and supplying replacement products that may be needed in a hurry. The company can also provide innovative custom solutions, including using non-standard materials. SNP holds ISO 9001 certification.

SNP is an exclusive distributor for US spray nozzle manufacturer BETE, for pre-treatment specialist Uni-Spray, specialist paper industry nozzle manufacturer ML Gatewood and tank cleaning systems manufacturer Dasic. In addition, the company supplier’s specialist washdown and disinfecting equipment from Lafferty Equipment and Guarany. Orders are handled quickly and efficiently from the company’s dedicated stock-holding facilities

01273 400092

info@spray-nozzle.co.uk

www.spray-nozzle.co.uk

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...