This is the fourth of eight articles from our Nozzle Knowledge series in which we look at the basics of spray nozzle systems. Prefer to watch a video version, please click here. Or, if you would like to download a pdf version, click here.

The impact a fluid has on a given target is extremely important for certain applications such as cleaning. Reach is defined as how far a given spray can be projected in a given direction and is clearly important for getting fluid where we want it to go. Impact and reach are fairly closely related properties and are affected by 4 key factors.

1. NOZZLE SIZE

This is a fairly straightforward relationship. The bigger the nozzle, the bigger the ‘K’ factor (each nozzle has a specific ‘K’ factor which is a constant that is specific to the nozzle. ‘K’ factors can be measured in different units but in metric units, the ‘K’ factor is defined as the flow rate in litres per minute at 1 bar) and the bigger the flow rate going through the nozzle which means the longer the reach and the higher the impact.

2. SPRAY PATTERN

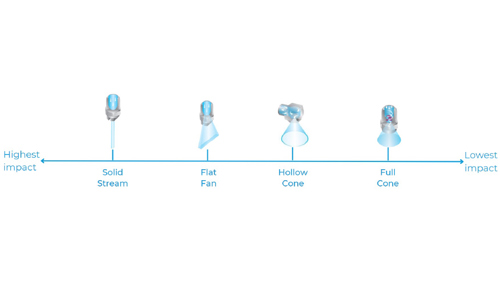

Spray pattern is the next factor and there is an order. The basic nozzle types in order of highest to lowest impact and reach are:

3. SPRAY ANGLE

The bigger the spray angle, the lower the impact and reach. Think of the spray pattern essentially in terms of concentration of a fluid; if a fluid is being distributed over a large area with a wider spray angle or a full cone or flat fan pattern as opposed to a solid stream nozzle, the energy will be distributed over a wider area. Therefore, it will have less impact and reach.

4. FLUID PRESSURE

This is a slightly complex and counterintuitive relationship. Generally, with solid stream nozzles the higher the fluid delivery pressure, the higher the impact and reach. However, increasing pressure to increase impact will be less effective in certain nozzles. If the nozzle is very efficient at atomising the spray (for example an impingement design misting nozzle) then increases in pressure will serve to atomise the spray into finer droplets. These inherently will have less momentum and so, even with increased flow rate, the overall impact and projection of the spray will hardly be affected.

Generally speaking, with hollow and full cone nozzles, the higher the pressure, the less reach we have, particularly in windy conditions or in gas flows.

Increasing the fluid pressure increases the overall internal energy of the fluid. How much of this increase in energy is used to atomise the spray and how much is used to increase momentum and impact depends very much on the nozzle being used.

General rules of thumb are that solid stream nozzles are the most efficient at transferring energy into momentum, followed by flat fans, then hollow cones, then full cone nozzles. It should be noted that often nozzles will be discussed as being very energy efficient. This means they are very efficient at using internal fluid energy to atomise the fluid and so in this respect are very inefficient at energy transfer.

About SNP

SNP aims to take the hassle out of procuring small engineering components such as spray nozzles with expert advice and product specification.

SNP supplies spray nozzle solutions to industries worldwide, including the largest engineering, food processing, chemical and petrochemical companies, as well as a vast array of small and medium sized enterprises (SMEs). The company’s product range includes tank washing nozzles, hydraulic nozzles, air atomising nozzles, custom piping assemblies and spray accessories as well as disinfecting and washdown systems.

SNP is as skilled in advising design engineers at the beginning of projects as it is recommending and supplying replacement products that may be needed in a hurry. The company can also provide innovative custom solutions, including using non-standard materials. SNP holds ISO 9001 certification.

SNP is an exclusive distributor for US spray nozzle manufacturer BETE, for pre-treatment specialist Uni-Spray, specialist paper industry nozzle manufacturer ML Gatewood and tank cleaning systems manufacturer Dasic. In addition, SNP supplies specialist washdown and disinfecting equipment from Lafferty Equipment and Guarany. Orders are handled quickly and efficiently from SNP’s own dedicated fulfilment facilities in the Midlands.

01273 400092

Spray Nozzle People Website

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...