This is the third of eight articles from our Nozzle Knowledge series in which we look at the basics of spray nozzle systems. Prefer to watch a video version, please click here. Or, if you would like to download a pdf version, click here.

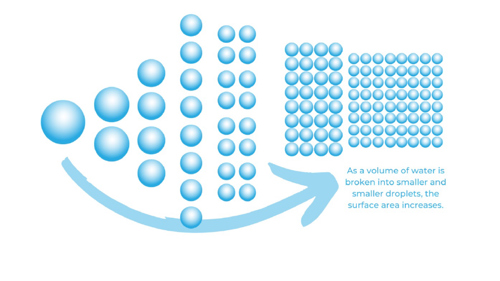

Drop size is a measure of the surface area of a spray and the smaller the drop size, the bigger the surface area. And the bigger the surface area, the more heat transfer and chemical interaction occurs.

Drop size is extremely important for many spray applications. But what factors affect drop size?

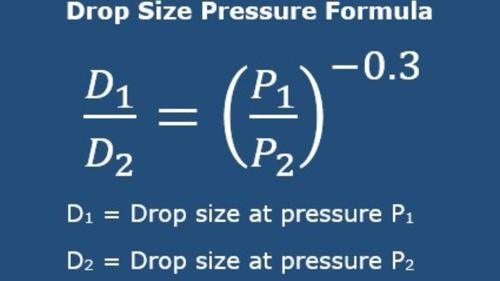

1. PRESSURE

Spraying at different pressures will generate different drop sizes. The higher the pressure, the lower the drop size. For any specific nozzle, this can be calculated using this FORMULA:

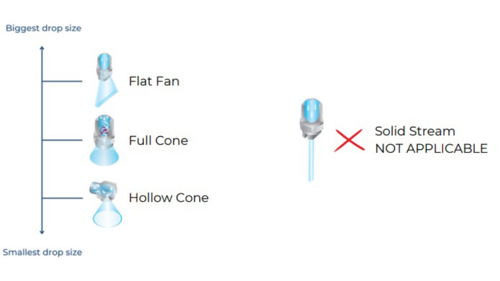

2. SPRAY PATTERN

There are four basic spray pattern types. Solid stream nozzles don't really have a drop size. Flat fan nozzles typically have the biggest drop size and then full cone nozzles and then finally hollow cone nozzles typically give the smallest drop size.

3. SPRAY ANGLE

Flat fans, full cones and hollow cones have a spray angle, and the wider the spray angle, the smaller the drop size will be. However, there is a slight peculiarity; the drop size tends to increase with some of the wider spray angles.

A 150 or 170 degree spiral nozzle for example, has a bigger drop size than a 90 degree nozzle of the same type.

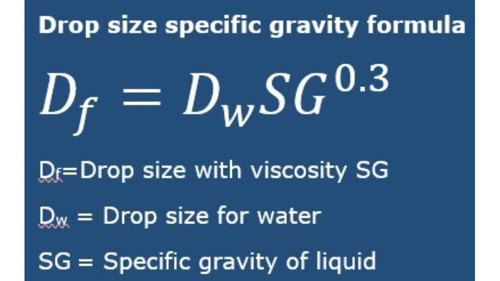

4. FLUID PROPERTIES

Basic drop size calculations will be calibrated for water. Therefore, different fluids will require the drop size to be adjusted for properties such as specific gravity, viscosity and surface tension.

Drop size can be adjusted for specific gravity of the fluid using this FORMULA:

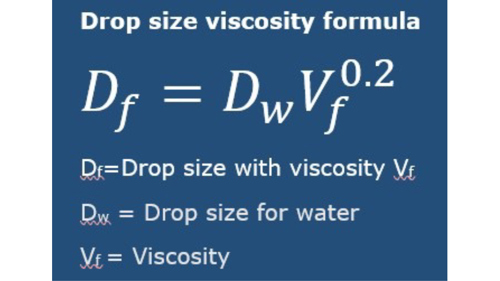

The viscosity of the fluid can also affect drop size and it can be adjusted for by using this FORMULA:

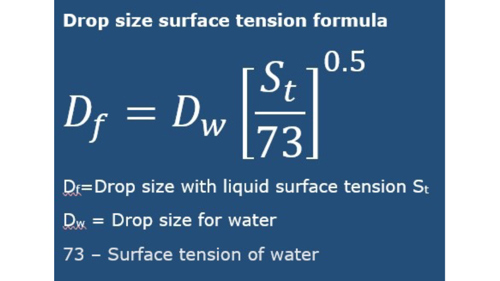

Surface tension is the other factor that can affect drop size and this can be adjusted for using this FORMULA:

Here at SNP, we have tools that can calculate all of this for you so please don’t hesitate to get in touch. For even more technical information, head to the resources page of our website here.

About SNP

SNP aims to take the hassle out of procuring small engineering components such as spray nozzles with expert advice and product specification.

SNP supplies spray nozzle solutions to industries worldwide, including the largest engineering, food processing, chemical and petrochemical companies, as well as a vast array of small and medium sized enterprises (SMEs). The company’s product range includes tank washing nozzles, hydraulic nozzles, air atomising nozzles, custom piping assemblies and spray accessories as well as disinfecting and washdown systems.

SNP is as skilled in advising design engineers at the beginning of projects as it is recommending and supplying replacement products that may be needed in a hurry. The company can also provide innovative custom solutions, including using non-standard materials. SNP holds ISO 9001 certification.

SNP is an exclusive distributor for US spray nozzle manufacturer BETE, for pre-treatment specialist Uni-Spray, specialist paper industry nozzle manufacturer ML Gatewood and tank cleaning systems manufacturer Dasic. In addition, SNP supplies specialist washdown and disinfecting equipment from Lafferty Equipment and Guarany. Orders are handled quickly and efficiently from SNP’s own dedicated fulfilment facilities in the Midlands.

01273 400092

info@spray-nozzle.co.uk

www.spray-nozzle.co.uk

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...