Run by IMechE, the competition sees students design and build drones to compete across a number of challenges. Although this year’s event was won by Team Hedef from Turkey’s Istanbul Technical University, teams from UCL featured prominently, taking three of eleven prizes.

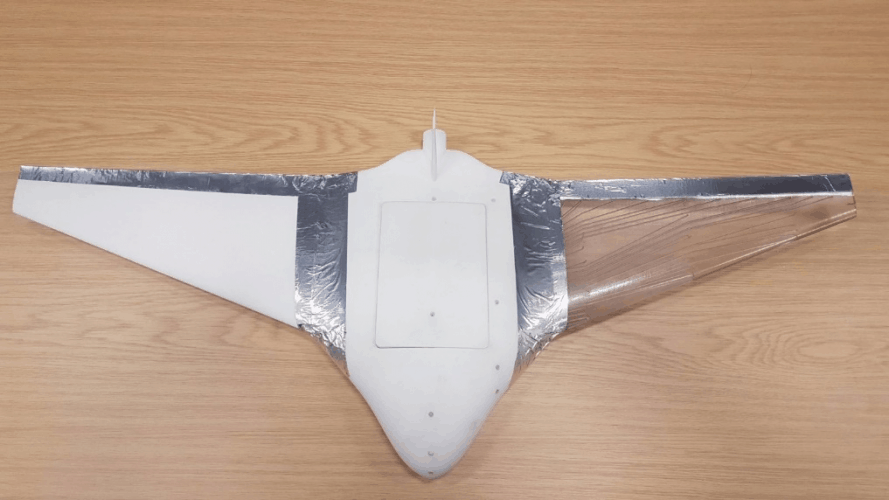

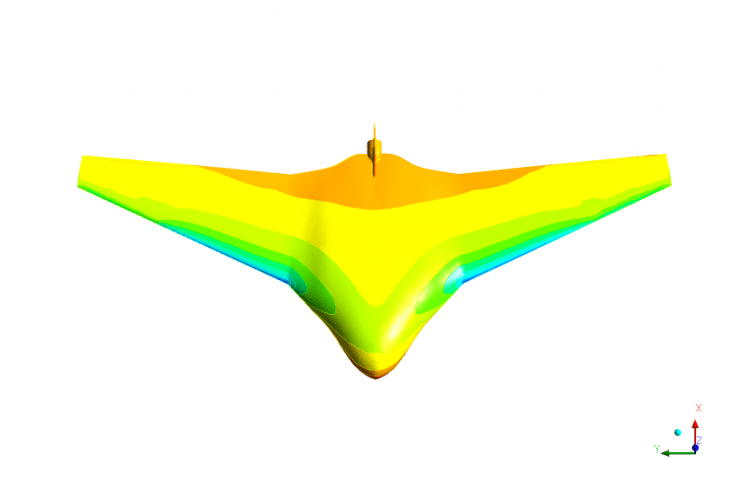

Project Bentham was one of two teams competing at the event under the university’s banner. It took a novel approach to the competition, developing a tail-less, blended-wing-body aircraft, which was to be made from carbon-fibre reinforced polymer. However, when it came to making the actual model, the team realised there were issues.

To develop a model capable of enduring wind tunnel testing is often expensive, especially if the specific part requires pressure taps essential to sampling the distribution of air across the prototype. It was when attempting to solve this issue that the expertise of Ogle Models was sought. The Letchworth-based prototyping company recommended using stereolithography (SLA) - a form of highly accurate 3D printing technology - which meant the pressure taps could be built within the model. This led to costs being significantly reduced

“Following the wind tunnel testing, the results converged across a range of angles of attack and yaw positions,” said Sam Hiscox, team leader for Project Bentham. “Pressure plots taken from the taps validated the aerodynamic properties of the design, which would not have been possible without Ogle’s expertise.

It was not the first time Ogle had worked with UCL students to assist with the demands of a high-level engineering competition. The prototyping company also helped the 2016 UCL Formula Student team bring its racing car to life.

“UCL is regarded as one of the best institutions in the country when it comes to training tomorrow’s mechanical engineers and we were only too happy to help when the team approached us,” said Matt White, senior sales engineer at Ogle.

Nanogenerator consumes CO2 to generate electricity

Nice to see my my views being backed up by no less a figure than Sabine Hossenfelder https://youtu.be/QoJzs4fA4fo