Researchers develop waste combustor

Researchers at Northeastern University have designed an apparatus to convert plastic waste into clean energy without releasing harmful emissions.

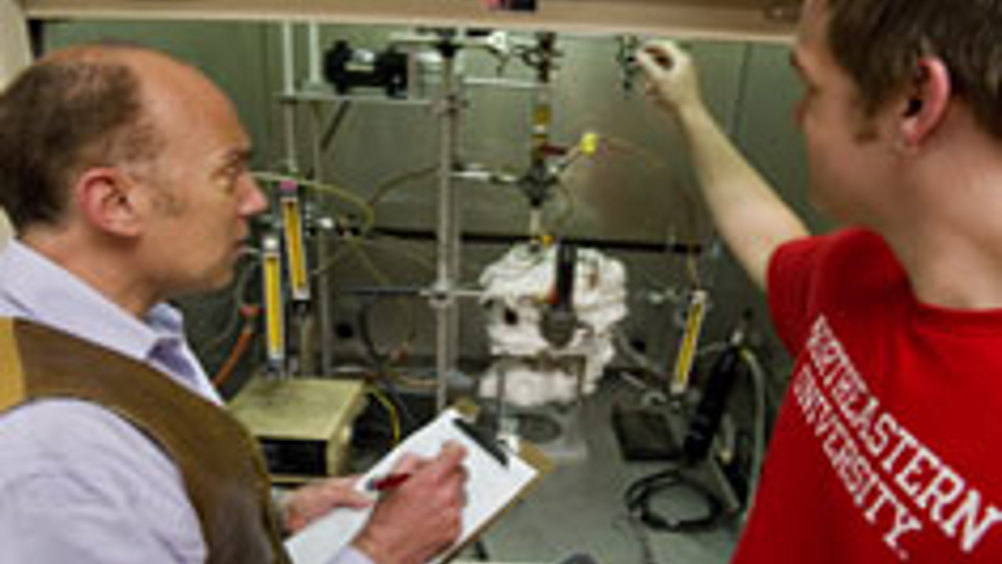

Under the leadership of Yiannis Levendis, a professor of mechanical and industrial engineering, a team of undergraduate and graduate engineering students developed the waste combustor, which breaks down non-biodegradable plastics to create an alternative source of fuel.

Plastic waste is first processed in an upper tank in the combustor through pyrolysis, which converts solid plastic into gas. Next, the gas flows to a lower tank, where it is burned with oxidants to generate heat and steam. The heat sustains the combustor while the steam can be used to generate electric power.

’The prototype can be scaled up to drive a large power plant, which could connect to a plastic recycling centre for a constant flow of fuel,’ said David Laskowski, an undergraduate student working on the team.

According to Laskowski, calculations show that the new technology has the potential of replacing up to 462 million gallons of petroleum in the US alone, if all recycled plastics were to be processed.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...