Laser ultrasound tests space rock stiffness

Researchers at Nottingham University have employed a new technique that allows for the elasticity and stiffness of space rocks to be measured for the first time.

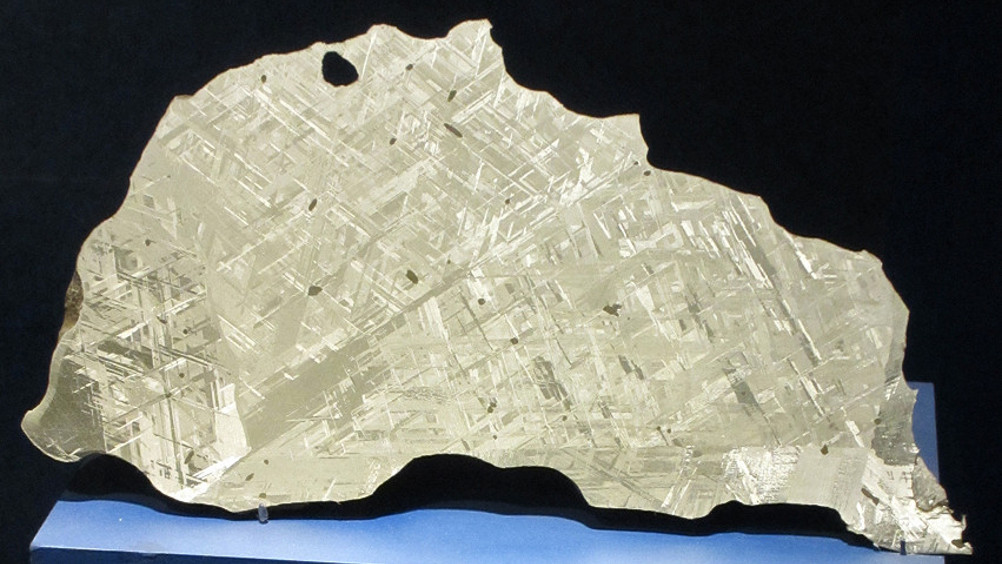

Described in Scripta Materialia, the method was developed and patented in-house at Nottingham. It uses a laser ultrasound technique known as spatially resolved acoustic spectroscopy (SRAS++) to non-invasively test meteorites and other space objects. The technique was used to examine fragments of the Gibeon meteorite, composed of an iron-nickel alloy and significant amounts of cobalt and phosphorus, which was discovered in Namibia in the 19th century.

The relative scarcity and scientific value of these types of space materials means that alternative, destructive testing methods are not appropriate. Additionally, many meteorites are made of crystalline materials that are formed under extraterrestrial conditions not achievable on Earth, meaning samples for destructive testing cannot be replicated.

“These materials have evolved in unique conditions over millions of years to form these amazing structures and patterns,” explained lead author Wenqi Li, from the University’s Optics and Photonics research group.

“These conditions cannot be reproduced on Earth and meteorites have amazing large-scale microstructure and phase mixtures which gives mechanical and elastic properties that are quite different to the man-made iron-nickel alloys we can produce on Earth.”

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

CCC Report Finds UK Climate Targets Still Within Reach

In 1990 67% of the UK´s electricity came from coal-fired power stations and even without renewables the transition to gas was a major contributor to...