Material’s secrets revealed with ultrasound scans of elasticity matrix

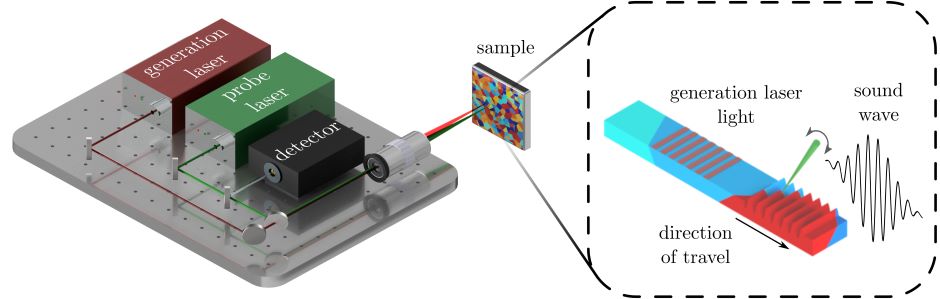

Researchers at Nottingham University have developed SRAS, a new technique that evaluates a material’s elasticity matrix by measuring the speed of sound across the material’s surface.

Claimed to be a world first, the innovation uses high-frequency ultrasound to produce microscopic resolution images of the microstructure and maps the relationship between stresses and strains in the material (the elasticity matrix). By precisely measuring the speed of sound across the surface of these crystals, their orientation and the elasticity of the material can be revealed.

According to Nottingham University, this EPSRC-funded technology is starting to be used in fields such as aerospace to understand the performance of new materials and manufacturing processes. The advance will also launch a new field of research as the technique is used as a completely new way to evaluate materials for improving safety in systems such as jet engine turbine blades, or in developing new designer alloys with tailored stiffness.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

One possible reform to the Asset Management Plan (AMP) system would be to stagger the five year cycle across the ten or so water businesses, so that...