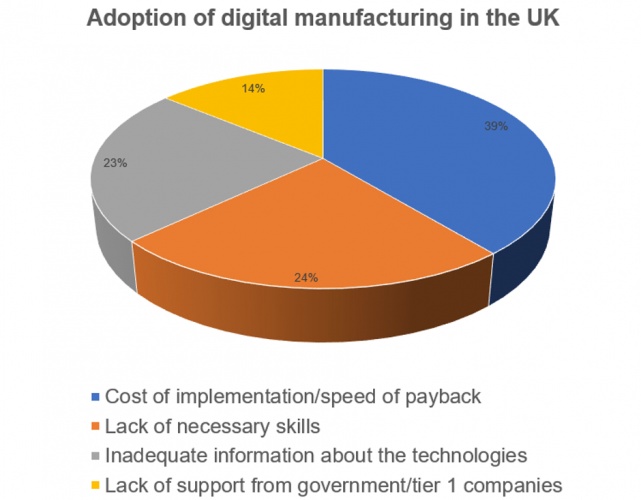

Last week’s poll: adoption of digital manufacturing in the UK

What is the biggest barrier to wider adoption of digital manufacturing technologies?

Digital manufacturing could help reduce production costs and decrease time to market, but uptake of these enabling technologies seems slow in the UK.

The umbrella term covers everything from robotics, digital twins and Internet of Things/industry 4.0 sensor-and AI-equipped equipment to additive manufacturing and computer-aided design and manufacturing IT tools.

The Digital Catapult estimates that the UK economy could grow by £455bn, create 175,000 new jobs increase productivity and cut CO2 emissions via the early adoption of advanced digital technologies in the next decade.

So, what is hindering the adoption of digital manufacturing in Britain? According to our poll, 39 per cent see the cost of implementation/ROI as the biggest barrier, followed by 24 per cent who see problems with skills deficiencies. This view is followed closely by the 23 per cent of respondents who feel they lack adequate information about available technologies, then 14 per cent who feel that government and Tier 1 companies are failing to adequately support industry uptake by smaller suppliers.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...