Vehicle development programs can be long and costly processes, but the automotive industry has made great strides in improving their efficiency over the years. One of the biggest breakthroughs has been in simulation and the associated digital revolutions that have led to a reduction of the number of physical prototypes required and the duration of projects.

But the R&D departments haven’t stopped striving for improvements and considering what might be possible in the digital age of vehicle development. There is a huge opportunity to bring scenario-based development into the virtual environment while, at the same time, retaining the core competence of Hardware-in-the-Loop (HIL) capabilities. This scenario is particularly advantageous where the quantity of physical testing required outstrips the amount of time and people available.

One specific example is autonomous vehicles, where the millions and millions of driving scenarios would require engineers to put a thousand vehicles on the road and drive them for a million miles each and then validate them all – clearly an impossible task. So, in that situation, testing moves to the virtual domain, where simulations can run at speeds much faster than real time.

Looking more nearer-term, the co-simulation of the ADAS function with vehicle drivability is another benefit of the new approach to vehicle development. The level of calibration is such that it will enable improvements in dynamics, comfort and efficiency in ADAS technologies to be made more quickly and easily.

Use of empirical digital twins

The critical element of scenario-based simulation is the use of empirical digital twins; such technology enables a variety of models and hardware to be digitally linked together in real time. The reason it is termed an ‘empirical digital twin’ is because it's built from laboratory measurement. In effect, a special kind of test plan is designed specifically to capture the behaviours of the unit under consideration. The data that gets generated is then turned into an empirical digital twin.

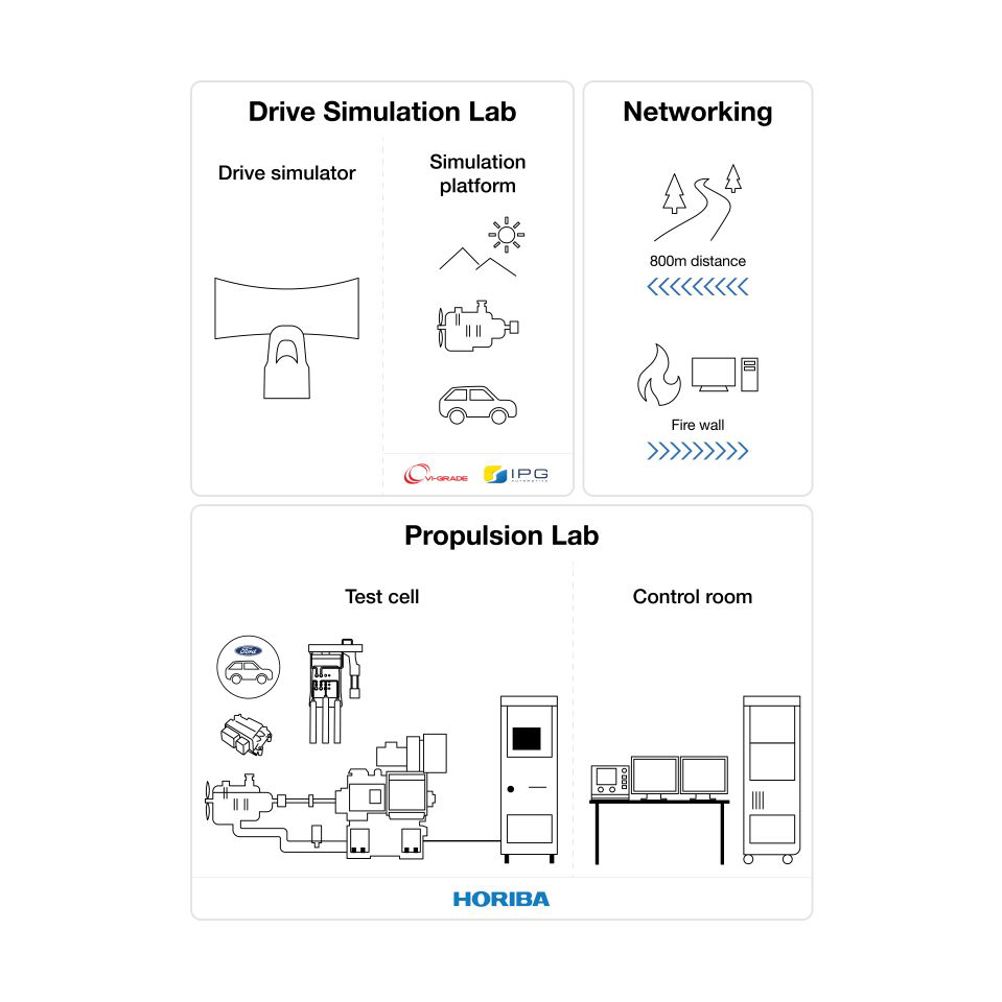

In a recent collaborative study, an empirical digital twin of a Ford PHEV powertrain was created by running transient cycles on a powertrain dynamometer and the outputs measured. This data training set was fed into HORIBA’s proprietary neural network machine learning algorithm to create a digital twin where the inputs match outputs of the real powertrain. The model had a highly accurate response for emissions, fuel consumption and state of charge of the battery relative to inputs such as pedal positions. That empirical digital twin was then run in parallel with a vehicle simulation, which included an environmental simulation.

The result? An ability to run scenarios much faster test than real-time – up to 50 times faster, in fact. So, a 90-minute road test that would typically require preparation and processing over the course of about two days, could all be done in 90 seconds. The numbers generated correlate very highly with those from a physical road test, too.

Don’t forget the prototypes

But it would be a brave person to say that co-simulation would eliminate all physical testing. If nothing else, the type approval and regulatory authorities require real-life testing, so until they accept digital engineering output, nothing will change there. However, what the approach does is enable hardware elimination, for example a 50 per cent reduction in the number of initial prototypes.

The big prize for a vehicle programme from using co-simulation is the removal of a phase. Typically, there would be a concept phase – where the architecture of the prototypes is defined – then the main development prototype phase before the production verification phase. The middle phase could potentially be completed using digital engineering. That means engineering teams can move straight from the concept phase to the production phase because they have enough confidence in meeting all the vehicle attributes thanks to all the work completed in the digital domain. Some of the hardware might be required for HIL so that there is a nice blend but, predominantly, this big development process really disappears thanks to co-simulation.

Big advantages to be gained

The benefits of this approach really vary depending on the specific project and OEM. In very broad terms, research suggests somewhere between €5 and €15m could be saved on a development programme just by deleting the vehicle prototype under the co-simulation approach.

In terms of time savings, HORIBA MIRA has conducted studies where validation using our digital twinning method took 15 days. Even if you had the perfect (very unrealistic) test programme – including teleporting vehicles to testing facilities – the minimum amount of time required is 45 days to run 90 road test evaluations. In that scenario, co-simulation brings a 70 per cent time saving, but it’s more likely to be closer to a 95 per cent time saving.

Another advantage of empirical digital twins is the ability to explore all areas of an operating design domain. For example, as it stands at the time of publication, Euro 7 states road tests may have 'any composition’. This flexibility in on-road testing is a double edge sword for test and engineering teams. On the one hand, physical road testing will become easier since any drive will be valid. However, vehicle manufacturers will have to ensure vehicle models remain below emissions thresholds across all parts of the Operating Design Domain. Empirical digital twins provide a convenient way to quickly and confidently explore many thousands of possible test permutations with co-simulation.

Project ViVID (Virtual Vehicle Integration and Development) is one study in particular drawing positive conclusions. This collaborative study between HORIBA MIRA, Ford of Britain, IPG Automotive, Loughborough University and the Institute of Digital Engineering (IDE), funded by the Advanced Propulsion Centre, has resulted in a whitepaper that outlines the opportunities of digital vehicle development.

Outside of the automotive market, this digital engineering approach could easily be replicated across all sorts of industries: aerospace, rail, drones and any form of transportation. Even domestic appliances such as washing machines could be developed in this way. It could also be used in manufacturing because you can simulate production lines and create a digital twin of a complex factory building.

For more information on the application of co-simulation technologies across the V-model, click here to read the Project ViVID whitepaper.

UK Enters ‘Golden Age of Nuclear’

I'm unfortunate to have no say in the matter but most of the UK's Nuclear Waste is stored about 11 miles from my home. Above ground still...