Simon McQueen-Mason, Network Director of The Lignocellulosic Biorefinery Network (LBNet), believes a bio-based green chemical revolution could transform UK industry.

Simon McQueen-Mason, Network Director of The Lignocellulosic Biorefinery Network (LBNet), believes a bio-based green chemical revolution could transform UK industry.

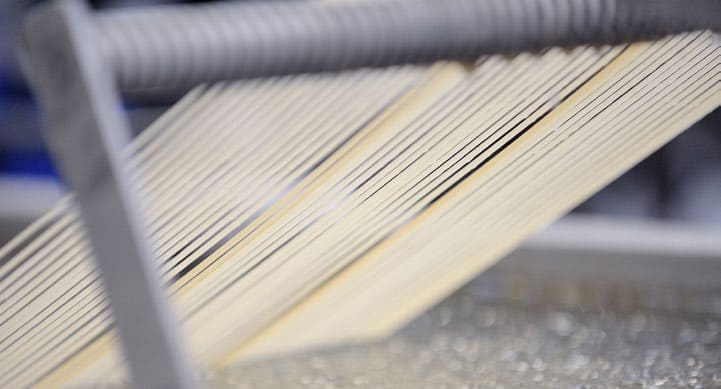

Many of the materials that go into engineered products and processes – from composites in cars and planes, to pharmaceuticals and industrial solvents – are made from chemicals derived from oil and gas.

As companies look for more sustainable supply chains a change is underway which will see many of these widely used chemicals replaced by similar chemicals derived from plants.

For those using these materials – as well as policymakers - this is an important trend, which they need to be aware of and factor into long-term planning. Rising oil prices, changing customer demands and new regulations are all likely to push traditional chemicals and materials up in price, whilst making bio-based chemicals more viable. But even before they reach price parity, there are often other advantages to these chemicals: sustainable production can offer a marketing benefit, and many bio-based alternatives have superior functionality or useful properties, such as biodegradability or reduced toxicity.

Furthermore, bio-based chemicals represent an important area of innovation, which – with the right support from business and government – could become a major industry and employer in the UK.

Right now, the UK is at crossroads in this area. We have world-leading research in bio-based chemicals in our universities, startups and corporate R&D. And there is growing interest from many engineering and manufacturing companies in these products. But there is a gap in turning R&D into commercial products that compete with petroleum-derived products on the open market.

Nonetheless, bio-based chemicals are coming. As oil falls out of favour, their rise is inevitable, and with the right support, this will be sooner rather than later. To this end, LBNet has produced a list of ten bio-based chemicals which present the best opportunities for the UK. These are chemicals where the UK has strong research foundations, and there is a clear benefit to existing industry. We hope this will help government and industry focus on identifying and developing the best opportunities for both the economy as a whole, and for individual engineering and manufacturing companies.

A whistle-stop tour of the Top Ten

The top ten includes green chemicals which can be used to make biodegradable plastics, medical parts, nylon, skin creams, and detergents. These feed into products that create billions in global revenue and are all currently made from petroleum.

Lactic acid, for example, can be used in the production of biodegradable polyesters, which could replace many plastics used in packaging, automotive parts, and textile fibres, allowing products to biodegrade instead of going to landfill. The biodegradability also has high-value applications in casing for medicines or medical screws which remain in the body after surgery.

5 Hydroxymethyl furfural (HMF) and 2,5-Furandicarboxylic acid (FDCA) are two versatile chemicals which can also be used to produce biodegradable materials, whilst making products more durable. Biome Bioplastics, one of the UK’s leading developers of natural plastics, has shown FDCA can be produced from natural sugars to make biodegradable food packaging and is now scaling this process up.

Levoglucosenone offers a safer and greener alternative to harmful solvents used in manufacturing. Australian company Circa has patented a process to do just that and has decided to focus its development in the UK to take advantage of our world-leading expertise.

Itaconic acid could replace petroleum-based acrylic acid: used in the production of superabsorbent polymers for nappies and personal care products; and unsaturated polyester resins, used in pipes, gratings and high-performance marine and automotive components. Chester-based Itaconix is developing hair care and laundry chemicals from itaconic acid, whilst pioneering R&D work is being carried out at the universities of Nottingham and York. Whilst the current market itaconic acid market is small, it has potential to tap into a market in excess of £10bn if it can reach price parity with petroleum-derived competitors.

Glucaric acid prevents deposits of limescale and dirt on fabric or dishes and could replace phosphate-based chemicals in detergents - over 4.5 million tonnes of which are sold annually - which are being phased out due to environmental concerns.

The full list is covered in our UKBiochem10 report, which also covers Levulinic acid, n-Butanol, muconic acid and 1,3-butanediol. These all have multiple useful applications which could replace and often improve upon widely used chemicals that are derived from petroleum.

https://www.theengineer.co.uk/green-alternatives-plastics/

Realising the bio-based potential

Ensuring these green chemicals meet their potential, and that the UK benefits, will need support from industry and government, and close collaboration between business and academia.

The most important areas where support is needed relate to furthering R&D and scale-up. In particular, we need new testing and scale-up services as well as open access piloting and demonstration facilities, which startups, academics and corporate R&D departments can use to collaborate.

Our hope is the list will help provide focus for both industry and government, showing where resources are best spent. From government, we are calling for policies to incentivise the use of these bio-based chemicals and targeting of funding towards developing and scaling up these specific chemicals. For industry, we hope this will help focus minds on planning R&D and identifying future supply chains, as well as inspiring collaborations to advance the development of these chemicals and the products which they will ultimately produce.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...