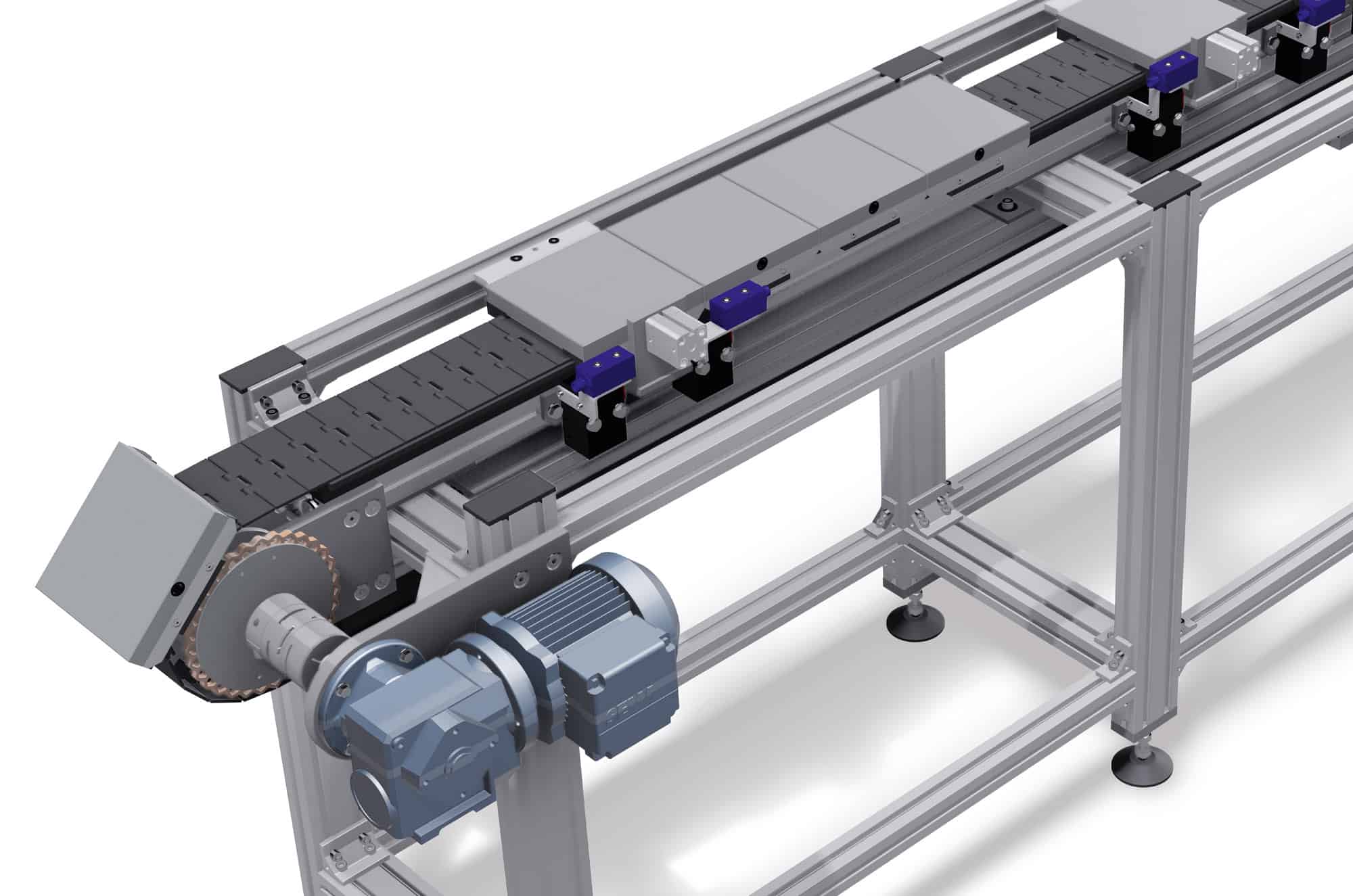

MK has expanded its portfolio in the field of automation: the new, accumulating pallet recirculation system SPU 2040 is integrated into its transfer systems range. It enables cost-effective and dynamic feeding, buffering, positioning and separating of workpiece pallets (WT).

When linking multiple workstations with different cycle or changeover times, the SPU 2040 allows a countercyclical operation with automatic recirculation of the WT. A flat top chain carries the workpieces on the WT to the plant. After removal of the workpieces the empty pallets are safely carried over the return roller and then conveyed back on the underside of the conveyor. They are then once again available at the starting point of the conveyor waiting to be loaded with new workpieces. A second conveying level and devices for lifting and lowering with complex control elements are no longer required. Neither is any additional manual or automated loading of pallets necessary.

The SPU 2040 is very compact. This means not only low space requirements, but also good ergonomic properties for workers that place or remove the components on the system. The SPU 2040 is suitable to use in measuring systems or supply in welding units, in the plastics industry, for automotive suppliers or manufacturers of machine tools for grinding or turning machines.

Due to its modular design and variable workpiece pallets, the SPU 2040 is adjustable and also offers flexibility. In single lane, dual lane or double lane mode it can be used for workpieces with different weight distribution. In addition to modules such as WT, transfer line, drive, return and frame, stoppers and separators, as well as different protective device guards, are available.

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...