This is the second of eight articles from our Nozzle Knowledge Series. Prefer to watch a video, click here.

Flow rate, the volume of water passing through a nozzle, per unit of time, is clearly an important factor in any spray nozzle. So, what affects flow rates and how do we calculate them?

Typically, flow rate is measured in litres per minute, litres per hour or possibly cubic metres per hour. It is extremely important to get the units correct and consistent and to note that flow rate refers to volumetric flow rate rather than a mass flow rate.

So, what affects flow rate?

There are 3 main factors: Size of the orifice, pressure and specific gravity of fluid.

1. SIZE OF THE ORIFICE

The size of the orifice is self-explanatory; bigger orifices will create higher flow rates and smaller orifices will create lower flow rates.

2. PRESSURE

How is flow rate calculated at different pressures?

Each nozzle has a specific ‘K’ factor which is a constant that is specific to the nozzle.

‘K’ factors can be measured in different units but in metric units, the ‘K’ factor is defined as the flow rate in litres per minute at 1 bar.

It is crucial to ensure that the ‘K’ factor is being measured in the correct unit.

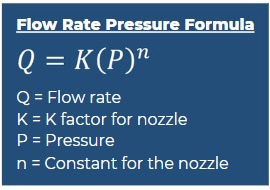

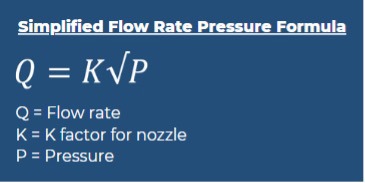

Once the ‘K’ factor has been established, the flow rate of a nozzle at any given pressure can be calculated USING THIS FORMULA.

For most nozzles, the exponent will be 0.5, which means the formula can be SIMPLIFIED TO THIS.

However, some nozzles have a different exponent and this can be 0.43 or 0.46. This can make a difference and so it’s important to understand the exponent specific to the nozzle.

For most purposes, it will be a root relationship with pressure. If the ‘K’ factor and exponent have been established, along with the pressure of the spray, the flow rate can be easily calculated. But to lend a helping hand, nozzle manufacturers produce spray flow rate charts for each nozzle with the calculations already done.

1. SPECIFIC GRAVITY OF THE FLUID

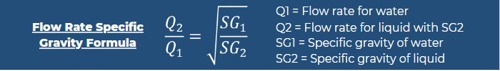

All of the data sheets available will calculate flow rates for water.

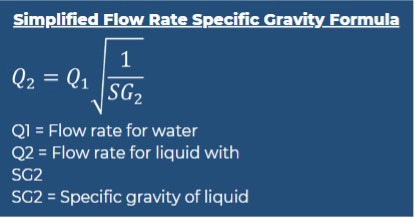

If a fluid with a different specific gravity and density needs to be sprayed, the flow rates must be adjusted accordingly using THIS FORMULA HERE.

If the flow rate for water has been established along with the specific gravity of water, this formula can be simplified TO THIS.

To conclude, the 2 steps to follow are:

1. Calculate the flow rate for water at the given pressure.

2. Use the formula to adjust it and establish a flow rate for the different fluid.

If you have any questions on flow rates and how to adjust and calculate them for different nozzles and fluids, please don’t hesitate to get in touch with one of our knowledgeable experts.

NEXT ARTICLE: DROP SIZE

About SNP

SNP aims to take the hassle out of procuring small engineering components such as spray nozzles with expert advice and product specification.

SNP supplies spray nozzle solutions to industries worldwide, including the largest engineering, food processing, chemical and petrochemical companies, as well as a vast array of small and medium sized enterprises (SMEs). The company’s product range includes tank washing nozzles, hydraulic nozzles, air atomising nozzles, custom piping assemblies and spray accessories as well as disinfecting and washdown systems.

SNP is as skilled in advising design engineers at the beginning of projects as it is recommending and supplying replacement products that may be needed in a hurry. The company can also provide innovative custom solutions, including using non-standard materials. SNP holds ISO 9001 certification.

SNP is an exclusive distributor for US spray nozzle manufacturer BETE, for pre-treatment specialist Uni-Spray, specialist paper industry nozzle manufacturer ML Gatewood and tank cleaning systems manufacturer Dasic. In addition, SNP supplies specialist washdown and disinfecting equipment from Lafferty Equipment and Guarany. Orders are handled quickly and efficiently from SNP’s own dedicated fulfilment facilities in the Midlands.

01273 400092

info@spray-nozzle.co.uk

www.spray-nozzle.co.uk

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...