The timer has started. By 2050, the UK has a target of Net Zero Emissions meaning any emissions generated must be balanced by schemes offsetting an equivalent amount of gas emitted. This could be performed through carbon offsetting programs, but ideally companies are looking to reduce, reuse or recycle more to meet these objectives sooner before carbon pricing comes into force.

But how can companies work towards achieving Net Zero with pumps?

Reduce

One method to reduce pump related carbon emissions is to reduce the power consumed, decrease the amount of wastage, lubricants spent, and spare parts consumed by the unit during operation.

In order to do this we need to look at becoming more efficient which is fairly easy if we are talking about one pump or application, but across a number of applications and with liquids varying according to what the process demands, it quickly becomes more complicated.

High Efficiency Pump Design are designs of pumps where internal tolerances are very close, ensuring energy is not lost through recirculation within the pump head, with maximum amounts of energy imparted on fluid which exits the pump head.

These types of pumps include Multistage, End Suction Centrifugal, and Piston/Plunger pumps. As tolerances are fine, viscous or solid laden fluids cannot be accommodated meaning their efficiency is limited to clean, low viscosity fluids.

Efficient designs also incorporate variable speed drives enabling the unit to produce a wide range of flow and pressures to accommodate varying demand in process. This technology is prevalent in applications where pumps are running continuously for example in cooling, pressure boosting or the circulation of hot water saving up to 50% of the energy required to transfer fluids.

Eco versions of pumps ensure pump head design is optimized for efficiency. Casing wear rings may be added to improve efficiency in particular when impellers have been trimmed, with the pump head shape design optimised.

To become more efficient with other process fluids such as chemicals, reducing the amount of wastage can be performed by ensuring bulk containers in which most blends of liquids are delivered in, are completely emptied. A 99.98% Barrel Emptying Kit ensures almost all of a containers’ liquids are emptied where normal designs typically only empty 95% of a containers’ contents. Where fluids are expensive, units can pay for themselves within only a few months of use.

With viscous or dry fluids Lowering Spare Part Consumption enables equipment to operate more efficiently. Designs such as Peristaltic or Progressing cavity which rotate slowly in particular with abrasive media ensures pump part lifespan is drastically increased.

Hose Pumps can operate as slowly as 1rpm drastically reducing wear when media such as grout, dehydrated sludge, or digestate are transferred. Peristaltic Pumps are seal less meaning seals are not present which can wear, degrade, or cause clogging. As the only wearing part is a hose, spares holding is significantly reduced, maintenance times improved and the main hose can be recycled reducing impact on the environment.

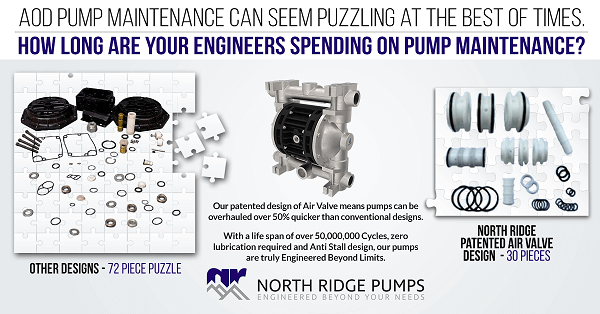

With other designs such as the Boxer range of Air Operated Diaphragm Pumps, they have been refined through R&D to contain fewer internal parts ensuring less parts are kept on hand for replacement, reducing the time taken for maintenance but also meaning that the unit can work more efficiently using less parts without adverse effect on performance.

The utilization of self-priming pumps as opposed to submersible pumps ensures longer pump lifespan as pumps are not immersed within the fluid reducing the amount of equipment, personnel and frequency of inspection.

Slurry Pump Design

With slurry pump design the use of front and rear adjustment bolts ensures internal wear plates are kept within close proximity of the impeller maintaining efficiency as they wear. Traditionally slurry pumps are sealed using Mechanical Seals which require a fresh water flush or gland packing which drips, acting as cooling whilst the pump operates.

Mechanical Seals which require a fresh water flush or gland packing which drips, acting as cooling whilst the pump operates.

Component Optimisation

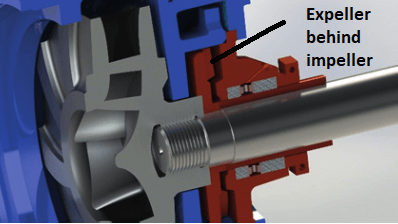

Expeller seal design is where a rotary disc shaped device similar to an impeller rotates as the pump shaft rotates, meaning the pump does not require a seal flush to maintain sealing. The expeller creates an area of low pressure around the shaft effectively creating a dynamic seal. The benefits of such a design mean a continuous fresh water supply is not required which is important when most mines are located within remote locations, where water is scarce vastly reducing water use, as well as operational costs.

Magnetic drive or Seal Less units means that units are designed in such a way that the unit is not prone to seal wear or leaking leading to loss of fluid from the pump head ensuring full containment.

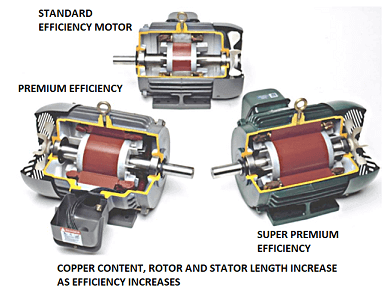

With the 2030 UK Ban of Diesel and Electric engines it is likely that driver design will be changed from engine driven to electric where possible. Upgrading drivers to Premium Efficiency Motors (currently IE3) which for a small motor <0.75kw are 83.5% efficient or at 75Kw are 95.4% to Super Premium Motors IE4 which are due to become mandatory in 2023 can further increase savings when switching from older designs of Motors. IE4 motors are rated at <0.75Kw up to 85.5% efficient and at 75Kw are 96.2% efficient.

Optimisation of Air & Electric Driven Pumps

There are specific conditions where air or electric pumps can be more efficient within process. The research paper "Electric or pneumatic? Comparing electric and pneumatic linear drives with regard to energy efficiency and costs" by Hirzel et al 2014 determines that electric drives can show a higher efficiency for shorter duty cycles, where as an Air Operated Diaphragm Pump with small strokes and longer cycles can have a lower energy demand than that of electric driven units.

System Optimisation

To maximise optimum operation of your pump and system the following should be checked:

Pumps In Parallel

To ensure maximum efficiency of pumps operating in parallel within a closed loop circulation system, pumps of the same type, model and with the same speed ratio should be operated with controls in place to make certain that the minimum number of pumps are operated. Source efficient_driving_at_variable_speeds_world_pumps_vol_2013_issue_4.pdf world Pumps April 2013

Pipework Routing & Size

The number of bends, material, diameter and length of pipework directly effects the pressure losses within the system and the amount of energy required to overcome such pressure losses. A common mistake is to size pipework according to the pump inlet diameter, or according to existing equipment. Pipework should be sized according to the required flow, ensuring that the pressure loss does not create a velocity in the fluid above 2M/s in the suction pipe, or 3M/s in the discharge pipework. Ideally head loss should be no more than 6%. Incorrect pipework size selection can create water hammer damaging pipework.

Filtration & Strainer Clogging

Filters and strainers can become clogged during operation and go unnoticed for periods of time leading to higher power consumption in pumps, and at worst case cavitation. The use of self cleaning strainers ensures filter mesh is always kept free from debris and produces very little pressure loss. Pressure differential switches provide visual and audible indication of strainers becoming clogged ensuring any issues are addresses quickly before escalation.

Reuse - Recycled or Dry Fluids

Another way to reduce the carbon footprint of companies undertaking processes such as jet washing, hydro demolition, paint, plastic or rubber removal from metal components for recycling, is to evaluate whether fluid recycling or reuse can be implemented.

Historically high-pressure jets of water are used to remove layers involving the pumping of fresh clean water, with water which has been spent, drained away or disposed of.

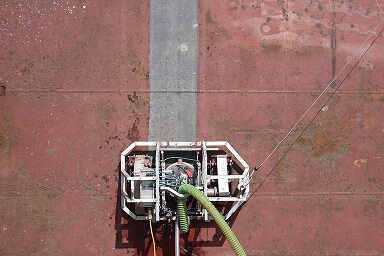

Pump designs are available which utilize recycled water enabling jetting fluids to be recycled and recirculated within the pump head vastly reducing water use. A device such as the North Ridge Hull Cleaner which can be adapted for similar processes, does not utilise grit or other media to remove coatings. Hydro-blasting also eliminates the costly use of sand or grit – the worlds’ second most consumed natural resource, is quieter, and ensures rebar is not damaged enabling its reuse.

Hydro-blasting is far more efficient too covering up to 30-40 square metres an hour as opposed to sand blasting using traditional methods which can only cover up to 10sqm an hour.

Recycle – Creating Energy in place of Pressure Reducing Valves

High pressures can often harm equipment further downstream from process or for safety reasons be undesirable if there is risk of pipeline equipment failure lead to fluid escape. Excess pressure in a pipeline is often wasted.

Excess pressure is reduced within process via the utilization of pressure reducing valves. Such valves reduce pressure with excess energy being left unused.

Using a Pump as Turbine enables this otherwise wasted excess energy to be converted into energy. The unit runs in reverse rotating a generator as the impeller rotates from excess flow and pressure. Unlike turbines, the payback can be as little as 2-5 years, and their uncomplicated design enables maintenance to be performed without special tools, knowledge or expertise. The unit can also function as a pump if required.

Processes to Reduce Natural Resource Consumption

Applications which can lead to a reduction in Natural Resources include:

Dewatering:In this process wastewater or sludges are treated with Coagulants, and flocculants to separate solids to produce a concentrated sludge with water being recycled. Another method is through the use of filter presses to squeeze water from fluids.

Concentrated Fluids:Fluids which are watered down, are likely to be used in concentrate form, with water added on site after transportation rather than before, increasing the amount of tonnage of raw material which is shipped on each delivery.

Liquid Organic Hydrogen Carrier Transfer:Hydrogen can be made safe to transport through the use of Liquid Organic Hydrogen Carriers. Benzene, Dibenzyltoulene, Napthalene, Toluene or derivatives can absorb hydrogen molecules into their structure, before later being dehydrated to release the molecules.

CO2 Capture & Storage:Projects involving Carbon, Capture and Storage are likely to increase as one method of controlling excess CO2. It can be used as a refrigerant, as dye transfer, concrete building materials, fuels, chemicals, and plastic.

Scrubbers: Where emissions are currently emitted on site or by ships, the use of scrubbers will be extended to reduce and eliminate polluting gases.

Nutrient Recovery – The recovery of Phosphorous and Nitrogen to be utilized within fertilizer manufacture can help prevent the formulation of algae within water course. Algae is a major contributor to low amounts of dissolved oxygen and fish mortality rate.

Working Towards a Zero Carbon Future Now

If you are looking at working towards a Zero Carbon Future today one of the first steps you can take is examining existing equipment for signs of inefficiency.

Here are 13 Checks you can make within your plant today:

1. Excessive throttling of pumps by valves

2. Continuous use of bypass lines leading to excessive amounts of fluid recirculation

3. Frequent spare part replacement of bearings, mechanical seals, and gaskets.

4. Cavitation with pumps operating noisily and consuming higher power than required.

5. Check Wear Ring Clearances. A 50% decrease in wear ring clearance can increase efficiency between 2-4% and reduce the risk of cavitation

6. Oversized pumps with units being frequently operated away from duty point.

7. Pumps with IE1 / IE2 Motors running continuously. Utilising a pump with a VFD can reduce energy consumption by up to 50%.

8. Checking for Air Leaks which can lead to savings of between 20-50%

9. Check whether heating of fluids will enable easier and lower energy methods of transfer, reduce pump wear and increase recovery rates from containers.

10. Check whether containers are being returned to suppliers which are still partially filled.

11. Check whether pumps operating in Parallel are utilizing inverters and appropriate technology to meet the required duty points against the system curve, or if one pump is in operation whether a second in parallel will improve pumping efficiency reducing overall power consumption.

12. Check pipework is sized correctly and renewed periodically to keep friction losses at a minimum.

13. If pump maintenance is reactive rather than proactive leading to downtime, and product wastage. Check whether the 6 to 1 rule is being followed.

How we can Help

As North Ridge Pumps are not tied to a single pump technology it ensures we select the most appropriate pump technology for your process, ensuring longevity, and productivity at the lowest Total Ownership Costs enabling you to meet your Net Zero target.

If you would like to discuss with a partner about making your pumping process more efficient to meet your Net Zero Carbon Goals Contact Us.

Water Sector Talent Exodus Could Cripple The Sector

'Capricious changes of priority by the general public'?!? Surely the public would demand both sufficient water supply and sufficient waste...