The Internet of Things is full of promises: smarter homes, better health and a unified, connected world. Less prevalent in mainstream media (but arguably more impactful to our society) is the Industrial Internet of Things (IIoT), with smart agriculture, smart cities, smart factories and the smart grid. The IIoT can be characterised as a vast number of connected industrial systems that are communicating and coordinating their data analytics and actions to improve industrial performance and benefit society as a whole.

Adding intelligence to industrial systems poses a number of daunting challenges: one of which is the concept of time within standard Ethernet protocols. We tolerate some level of lags, delays and reloads while watching Downton Abbey on BBC iPlayer, but these glitches cannot exist between two high-speed robotic arms assembling a medical device, or worse yet, between your brake pedal and the wheels of your car. Using standard Ethernet to bring together our cities, power grids and machines means we have to address its temporal shortcomings.

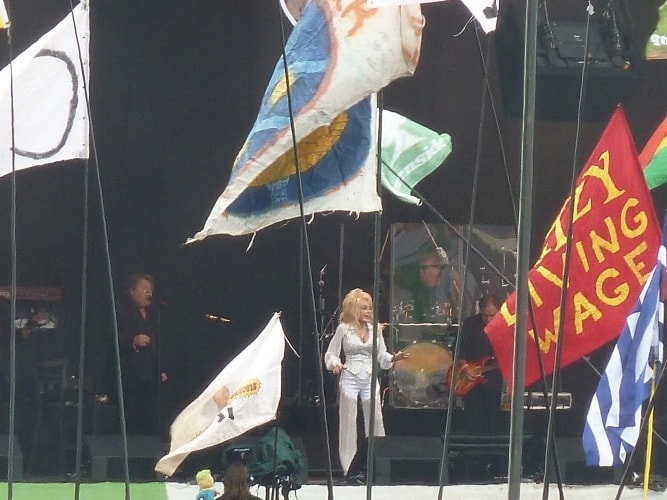

Fortunately, the music industry has provided us with a solution. Dolly Parton performed to 100,000 people at Glastonbury last year. While Ms. Parton certainly put on a memorable show, the engineers behind the scenes also performed admirably to ensure the audio and visual experience was excellent, even to people standing hundreds of yards away. This was accomplished through an incredible array of cables and carefully calibrated system components.

For years, replacing miles of A/V cables with standard Ethernet has been a dream of festival organisers, stadium designers and home cinema enthusiasts. Yet the same inherent networking challenges mentioned above, such as latency, poor reliability and synchronisation issues, have always proved insurmountable.

To address this, the IEEE 802.1 working group created an “Audio Video Bridging (AVB) task group”, which updated the Ethernet standard to include AVB in the late-2000s. AVB enables the deterministic streaming of audio and video data and the synchronisation of end nodes, such as speakers and “Jumbotrons”, over standard Ethernet. What’s more, AVB runs in parallel over the same Ethernet cable used to send normal data between computers.

How does this relate to the Industrial Internet of Things? The leap from Glastonbury to the smart factory might seem like a big one, but AVB can help us realise three steps in building the Industrial Internet of Things:

- Factories of the future will require machines to communicate, collaborate and synchronise with each other far more reliably and deterministically than today

- The walls separating machines from servers, data, analytics and visualisation need to be torn down and these systems integrated

- 50,000,000,000 devices will need to communicate and work together

Enabling the Industrial Internet of Things was one of the reasons the IEEE 802.1 AVB task group expanded and rebranded late in 2012 to become the “Time-Sensitive Networking (TSN) task group”. The task group is expanding AVB’s essential characteristics to support industrial automation, automotive control networks, and further improve audio/video applications. With TSN in place, the technologies for Ethernet communications, deterministic data transfer and node synchronisation will converge into a single new protocol.

With TSN, industrial designs will benefit from:

Convergence: One standard Ethernet backbone will support both high-priority control data as well as concurrent support for other Ethernet traffic. Because the high-priority traffic is managed and protected, additions of other traffic cannot interfere with the control data

Performance: Standards bodies and major technology companies are constantly working together to improve Ethernet. This has led to vast increases in bandwidth, improved interoperability, and decreased commissioning time. With TSN, standard Ethernet will expand to support deterministic transfer of data measured in the tens of microseconds and time synchronisation between nodes measured in the tens of nanoseconds

Cost: By using standard Ethernet components, the cost to achieve TSN levels of determinism synchronisation between IIoT nodes will be much lower than using specific cabling or boutique Ethernet variants.

The sceptics among you will correctly point out that Ethernet on the factory floor is nothing new and that there is no shortage of network protocols and topologies for motion control, safety systems, sensor networks and machine-to-machine (M2M) communication. The sheer number of these kinds of industrial networks hints at the time, money and overall complexity in building even a mildly intelligent machine, let alone a smart factory that fully embraces the promise of the IIoT. By adopting TSN as the common thread that binds industrial systems together, we can begin designing industrial systems holistically with consistent interfaces, tightly synchronised timing throughout and simplified system level validation. Distributed real-time system designers call this temporal composability and it certainly doesn’t stop with the smart factory. Imagine your car, home or any other system that is composed of distributed computational nodes. All of these systems will eventually benefit from Time-Sensitive Networking. I think Dolly would be proud.

By Kyle Voosen, Marketing Director, Northern Europe, National Instruments

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...